Based in Nashua, New Hampshire in the US, ImageXpert has been creating print quality assessment systems since 1989. The business began specialising in inkjet development systems in 2008 with the success of its JetXpert Dropwatcher. Since then, ImageXpert has expanded to R&D and pilot-production printers for its global customer-base, focused on accelerating development and refining a wide variety of manufacturing processes.

Alongside its analysis and printing equipment, the company provides printheads, drive electronics and fluid management systems for the testing and optimisation of its customers’ print systems. Therefore, it is crucial that the fluid management systems chosen are reliable and offer the capability to be used across a wide range of applications and printhead types.

ImageXpert recommends Megnajet fluid management systems for use on JetXpert and JetXpert Print Station systems. Initially, ImageXpert dropwatchers and Megnajet LC LFR products provided the foundations of the working relationship. The collaboration continued with the use of Megnajet’s CIMS II and Labjet products and more recently the RackFit (RFS), rack-mounted, compact fluid management system has become the product of choice over the last two years.

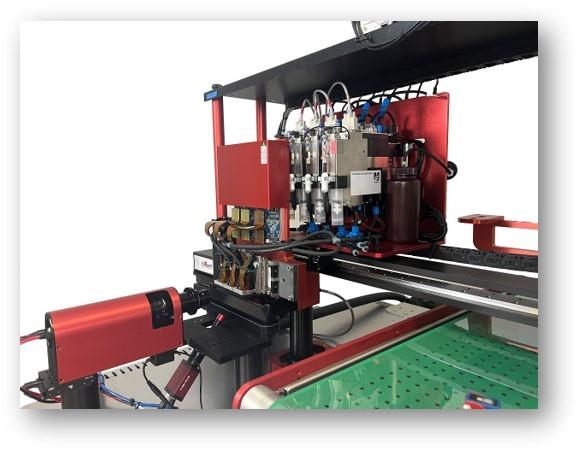

The Megnajet RackFit is a high-quality, compact fluid management system designed to be rack mounted for ease of integration and scalability. It’s ‘blade’ configuration allows ImageXpert customers to stack multiple units side-by-side to create the ultimate compact fluid management engine.

Kyle Pucci, Director of Applications Engineering at ImageXpert said: “We invested in Megnajet equipment early on and as a supplier it has been consistently reliable and a trusted partner from the very beginning.

“The Megnajet RackFit packs incredible capability, polished design, and high reliability into a small footprint that is perfect for the lab space, making it ideal for use across a huge range of our clients’ applications.

“Megnajet systems are extremely versatile, offering gravity-feed and recirculation, heating, degassing, and more – making it a great match for our customers who are experimenting with a wide variety of printheads and inks.”

The two companies take pride in their excellent communication and long-standing trust, even from opposite sides of the Atlantic. Working closely has been key to the success and ultimately improving the experience for customers.

“We’re really proud of our established partnership with ImageXpert and being part of the technology that has seen both companies grow together over the past decade has been fantastic,” said Adam Eaton, Engineering Manager at Megnajet.

“ImageXpert has been instrumental to our growth and exposure to a wider market, and we are pleased to see the versatility and reliability of our systems have been fundamental to this. We now look forward to our future work with ImageXpert and continuing to build upon a very successful decade.”