With its sleek design and innovative features, this machine embodies the pinnacle of modern casting technology, setting new standards for quality and performance in the industry.

At the core of the Scott AM 1000 series is its advanced automation capabilities, which streamline the casting process and ensure unparalleled quality and consistency. Automatic mixing and pouring operations, coupled with programmable PLC control, empower operators to achieve optimal results with every batch, reducing variability and maximising efficiency.

Our new machine delivers exceptional results, meeting the requirements of the most demanding projects.

The maximum recommended mould size is (H x W x D): 480 mm × 440 mm × 420 mm (18.9 in × 17.3 in × 16.5 in)

In anticipation of our new machine, we completed a vacuum casting room refurbishment, ensuring that the machine seamlessly integrated into our existing workflow. This investment underscores our dedication to providing our customers with the highest quality manufacturing solutions and unparalleled service.

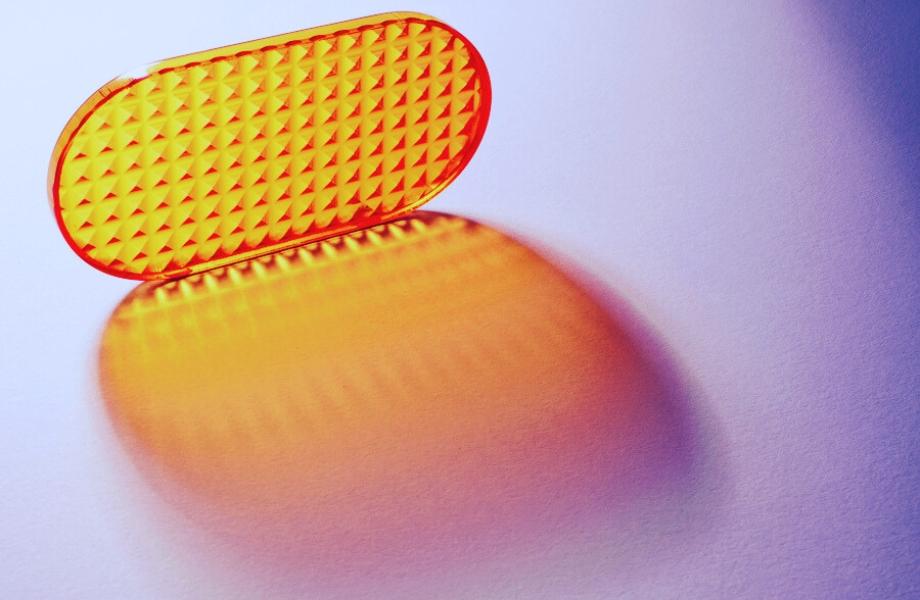

In terms of finishing options, functional parts such as elastomeric seals are usually just cleaned. Parts for visual models or functional prototypes are likely to be self-coloured by using pigments in the base material. We can assemble vacuum cast parts with prototype parts or off-the-shelf components. If other parts need to be attached with screws, we normally use cast-in threaded inserts. Blackout/EMI/RFI coatings can be applied to internal surfaces, and parts can be vacuum metallised.

Talk to us

Click here to learn more about Vacuum Casting service or, to discuss your specific requirements (or ask more about our vacuum casting investment), please contact us on 01763 249760 or request a quote.