3D printing with SLA

SLA is a versatile, cost-effective and quick technology for 3D printing prototype and end-use parts. Here at Prototype Projects, we have six SLA machines with build envelopes ranging from 250 x 250 x 250 mm up to 508 x 508 x 534 mm, so we can 3D print small, medium-sized and relatively large parts.

Furthermore, we build SLA parts in a choice of resins so the finished parts possess the required material properties:

- Accura ClearVue: a tough, durable clear resin.

- Accura 25: a tough, durable, cream-coloured resin, this resin offers a little more flexibility than Xtreme.

- Accura Xtreme: a tough, durable, grey-coloured resin.

Parts made from these three materials are non-porous and we offer a number of finishing options. Accura ClearVue can be polished and lacquered for creating parts with improved clarity. In addition, all three materials can be primed and painted, and have blackout/RFI/EMC coatings applied to internal ‘B’ surfaces. The materials are sufficiently tough that they can be tapped or have threaded inserts installed, depending on the thread size.

3D printing with PµSL

PµSL takes 3D printing to a level that was not previously possible. With far better resolution than other 3D printing technologies, PµSL delivers exceptional accuracy and smooth surfaces. The disadvantages of PµSL are that it is a slower process because the layer thickness is so small, and the parts themselves are smaller. Our PµSL 3D printer has a build envelope of 100 x 100 x 75 mm, which is much less than our smallest SLA 3D printer.

We use three different materials in our PµSL 3D printer, all of which are relatively stiff and strong when cured. Prototype and end-use parts, therefore, benefit from good dimensional stability and fine details that retain their as-built accuracy.

- HTL resin: a black/carbon black high-performance engineering material with excellent strength and rigidity, and minimal water absorption. Parts withstand temperatures up to 114°C and can be sterilised in an autoclave.

- BIO resin: this material is suitable for non-implantable medical parts requiring biocompatibility, having passed ISO 10993 biocompatibility tests for skin irritation and sensitization, toxicity, cytotoxicity, pyrogenicity and in vitro hemolysis. The cured resin is transparent yellow, can be sterilised and has lower water absorption than HTL resin. BIO resin’s tensile strength and flexural strength are marginally lower than those of HTL resin.

- RG resin: a versatile grade for durable end-use parts or prototypes intended for functional testing. Cured RG resin is biocompatible and does not absorb moisture. As with BIO resin, RG resin is transparent yellow. Cured RG resin has a tensile strength that is between that of BIO resin and HTL, the flexural strength is lower than for either HTL or BIO, and elongation at break is the highest of the three resins.

In theory, the three PµSL materials could be finished in much the same way as SLA parts. However, secondary finishes are seldom requested because they would have an adverse impact on the parts’ tight tolerances and fine details.

Combining SLA and PµSL

Sometimes you might need the size, speed, accuracy and cost-effectiveness of SLA while at other times the extreme accuracy of PµSL might be required for small components. Inevitably, there are occasions when you need a relatively large part that incorporates high-accuracy detailed features. Making such parts entirely using PµSL would be expensive, slow, and it may be necessary to 3D print the part in multiple sections for subsequent assembly.

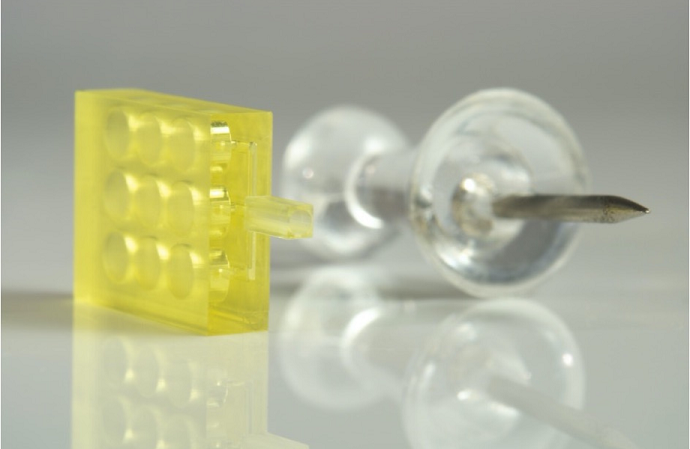

An alternative approach is to use SLA and PµSL to 3D print different sections of the same part then assemble them so you have the best of both worlds. Not only will the part benefit from the size, speed, accuracy and cost-effectiveness of SLA, but the critical features also have the high accuracy and smooth surface finish of PµSL.

SLA parts can have location features 3D printed to enable PµSL elements to be positioned accurately ready for snap-fitting or adhesive bonding. Alternatively, an SLA part can be CNC machined accurately for accepting PµSL inserts; this can be a particularly useful method if two or more PµSL elements need to be positioned accurately relative to each other. Another option is for a CNC machined element to be used for locating the PµSL features prior to the whole sub-assembly being fixed within the SLA part, or a CNC machined fixture can locate the parts accurately while they are bonded in position.

Applications for combined SLA and PµSL parts

Combined SLA and PµSL parts can be suitable for producing one-offs or multiple prototypes, perhaps for proof-of-concept studies or functional testing. The combined 3D printing technologies are equally useful for manufacturing low volumes of end-use parts.

Typical fields of application include microfluidics, drug delivery devices, life sciences and biotechnology, though other sectors can also benefit from combining SLA and PµSL.

Dispatch times

Assembling parts that have been made by SLA and PµSL requires more time than just 3D printing parts due to the additional process steps involved, so we cannot offer an Express Delivery service. However, if you tell us what you need and how quickly, we can quote for making combined SLA and PµSL parts that meet your requirements.

Talk to us

If you would benefit from combining SLA and PµSL 3D printing technologies for prototyping or end-use applications, talk to our experts by calling 01763 249760, or complete the enquiry form below to request a quote.