The CAM622 connects to a sensor, measures the angle of a contactless rotating target, and generates industry standard quadrature encoder ABN outputs in response. Like CambridgeIC's existing processor ICs, sensors comprise special coil patterns manufactured using standard PCB fabrication. CambridgeIC designs compatible sensors and makes them available to customers. This approach makes sensors robust, precise, compact and cost effective to manufacture.

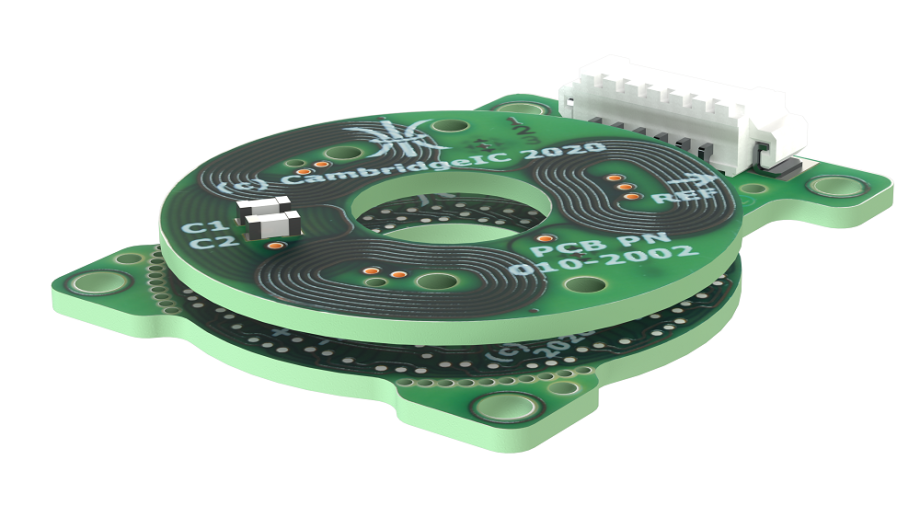

The CAM622 extends these benefits to the manufacture of targets. By increasing the operating frequency and reducing the minimum allowable quality factor of the resonator, the CAM622 is able to work with targets built from coils on a PCB. Targets comprise a disc shaped PCB with two surface mounted capacitors that form a resonant circuit. Resonant targets achieve far greater performance and gaps than standard inductive position sensing, and they eliminate the need for calibration. A range of sensors and targets is available, including outside diameters of 25mm, 30mm and 50mm. These have progressively larger centre holes, with the 50mm B5 sensor and target able to accommodate a 30mm diameter through shaft.

The new style of sensors and their matching targets are referred to as Type B. Like CambridgeIC's existing technology, there is no need for precise alignment when mounted inside a customer's product. Type B Sensors and Targets are both designed with a high degree of balance and symmetry. For example, the 25mm B3 Sensor achieves better than ±0.14° linearity error when the gap between sensor and target is between 0 and 2mm, with ±0.3mm radial and ±0.3° tilt misalignments. By accommodating such large misalignments, the technology gives customers the freedom to use conventional mounting methods such as screws, which further reduces integration cost.

The CAM622 includes circuitry to generate quadrature ABN outputs at up to 16 bit angular resolution. This means it can replace optical encoders, eliminating any accompanying bearings, seals and housings. The resulting mechanical assembly is far simpler, delivering a more cost effective measurement solution overall. Furthermore, the CAM622's ABN outputs are fully programmable, including cycles per revolution and N pulse position. A single hardware design can support multiple applications with only software customisation, without the need for multiple hardware variants and mechanical adjustment.

To meet the needs of even the most dynamic control systems, the CAM622 features an internal sample rate of 33,000 independent measurements per second. This is more than 6 times faster than the previous benchmark set by the CAM502. The frequency of the CAM622's ABN ouptuts updates every measurement. This ensures that the ABN count value keeps pace with actual position, even under extreme acceleration. As for extreme rotational velocities, the CAM622 is tested at up to 66,000rpm with the 25mm B3 Sensor.

A CAM622 ABN Board is available. This connects to any of the new Type B sensors. It includes the CAM622 processor together with external circuitry to deliver differential ABN outputs from a 5V supply.

The CAM622 will be on show in public for the first time at the SPS show in Nuremberg from 12 - 14 November. For a demonstration, visit CambridgeIC at in Hall 4, stand 174, where we will be joining our distributor MEV.