A pioneering study at the National Structural Integrity Research Centre (NSIRC) and Lancaster University is poised to revolutionize the future of fusion reactor development.

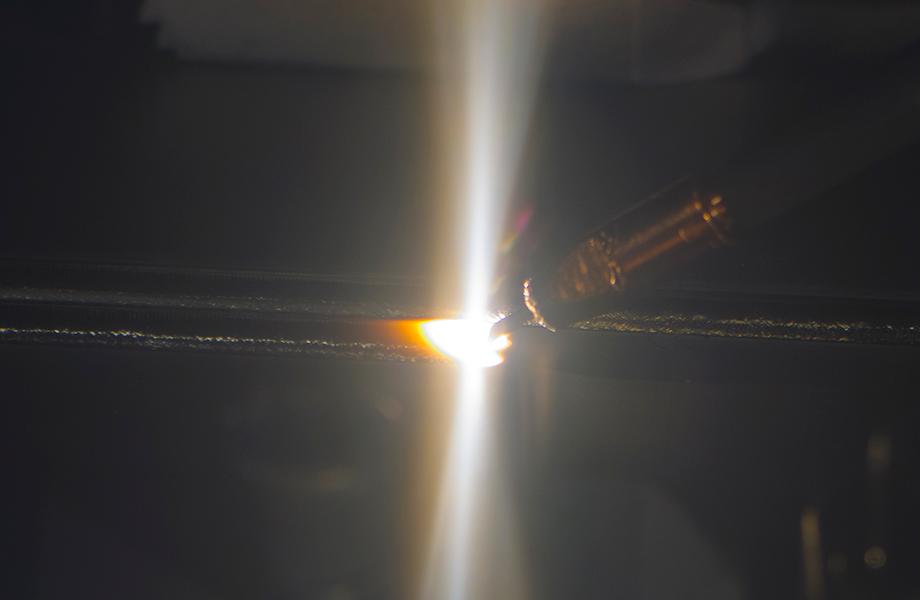

Spearheading this transformative research is Siyu Xu, a PhD student at NSIRC and Lancaster University, sponsored by TWI and Lloyd’s Register Foundation. The focus of the innovative project is the advancement of manufacturing pure tungsten for first wall applications in fusion reactors, using wire-fed electron beam additive manufacturing (WFEB) and harnessing the power of artificial intelligence for quality assurance and efficiency enhancements.

The research, titled, "Investigation Into In-line Process Monitoring for Improved Quality Assurance Using Artificial Intelligence in Wire-fed Electron Beam Additive Manufacture," exhibits the ambitious scope and impact of the project. By utilizing WFEB techniques, the project aims to manufacture pure tungsten components with high density, minimal porosity, and optimal mechanical properties, with the support of AI-driven in-line process monitoring for quality assurance.

The wire-fed techniques present a revolutionary approach compared to traditional powder bed methods, offering advantages such as higher purity maintenance, minimized oxidation risks, better material utilization, and improved material uniformity.

This research endeavors to explore the feasibility of manufacturing pure tungsten using WFEB, incorporating advanced machine learning techniques to optimize the manufacturing process. The application of AI for in-process monitoring and quality assurance aims to overcome current challenges in tungsten fabrication, establishing a reliable and efficient method for producing high-purity tungsten components.

With collaborations between NSIRC, TWI Cambridge, and Lancaster University, this study is expected to deliver groundbreaking outcomes that will drive innovation and efficiency in advanced manufacturing processes. The implications of this research are far-reaching, with the potential to reshape the landscape of fusion reactor development and usher in a new era of advanced manufacturing processes.

The collaboration between NSIRC, TWI and Lancaster University promises to yield significant advancements that will propel the industry forward into the future.