Revolutionizing Micro 3D Printing with Tough Carbon Black

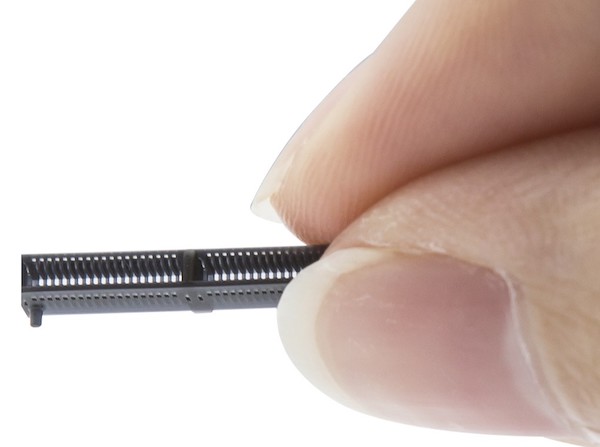

IPFL introduces Tough Carbon Black, a groundbreaking material that combines exceptional strength, flexibility, and high opacity, making it a game-changer in micro 3D printing. This material is designed to excel in producing durable, end-use components, particularly for applications where parts endure repetitive stress, such as snap-fits and electrical connectors. With its advanced mechanical properties, rapid print speeds, and low viscosity, Tough Carbon Black is tailored for industries like medical, defence, and aerospace, enhancing the performance of sensors, optical devices, and component housings.

Exceptional Durability for Challenging Applications

As a key addition to IPFL’s cutting-edge material lineup, Tough Carbon Black embodies innovation in precision manufacturing. This material sets a new standard in micro 3D printing, offering a unique combination of robustness and flexibility that meets the rigorous demands of sectors like medical technology, aerospace, and defence. Its high opacity and resilience ensure reliable functionality for components such as sensors and optical devices, even under intense operational conditions.

Engineering-grade resin for Long-Lasting Performance

Crafted as an engineering-grade photocurable resin, Tough Carbon Black delivers outstanding toughness, making it the ideal choice for critical components like housings and electrical connectors that demand both strength and longevity. The resin's low viscosity enhances its printability, enabling faster production cycles while maintaining precise quality.

Advancing Precision in Micro-Manufacturing

Tough Carbon Black supports ultra-fine resolutions and tight tolerances, addressing the complexities of microscale manufacturing with remarkable efficiency. By reducing production costs and lead times, this innovative material helps industries achieve new levels of precision and functionality. Its introduction reinforces IPFL’s dedication to providing materials that meet the intricate needs of specialized industries, setting new benchmarks in micro-manufacturing.

About IPFL

With over 55 years of expertise in plastic manufacturing, IPFL continues to lead the way in delivering innovative solutions for bespoke component production. Our extensive range of services and materials supports the evolving needs of industries worldwide, emphasizing precision, quality, and reliability.

To learn more about Tough Carbon Black and the advanced BMF S230 system with 2µm resolution, or to explore our full range of services, contact IPFL today.

Contact Details

Adam Bloomfield

Additive Manufacturing Manager

IPFL

Phone: 01992 893231

Email: sales@ipfl.co.uk

Website: www.ipfl.co.uk