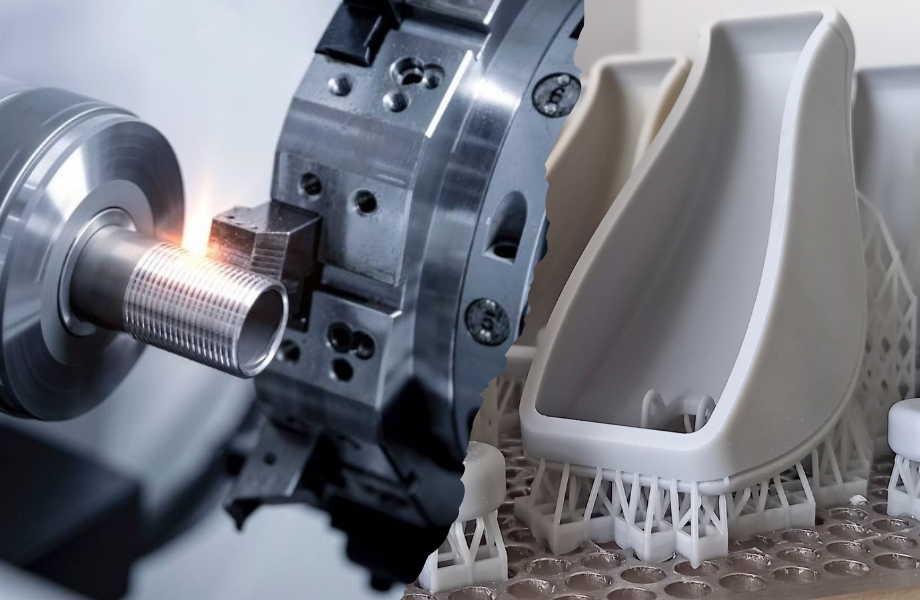

Subtractive and additive

When making a part by CNC machining, the process starts with a solid material (a ‘blank’) and the machining process employs a variety of cutting tools to remove material, little by little in accordance with programmed toolpaths, to leave the required geometry. CNC machining is referred to as a subtractive process because it removes material to create the part.

In contrast, 3D printing builds the part layer by layer. SLS does this by means of a high-power laser that fuses a fine powder, while SLA, PµSL, DLP and PolyJet build parts from light-curing liquid resins (photopolymers). 3D printing is therefore known as an additive process.

It is sometimes said that subtractive processes are wasteful in terms of material utilisation, compared with additive processes. This may be true, depending on the part geometry. Nevertheless, for most projects in which we are involved, the material cost is only one of many factors to be taken into account when choosing the manufacturing technology, and it is unlikely to be the decider.

Material choices

Whether the part is for a prototype or an end-use application, the designer will know what material properties are needed, bearing in mind the part’s functional requirements and its operating environment. Material properties can often be crucial in the decision whether to use CNC machining or 3D printing – even if it means the part geometry has to be modified slightly to improve machinability or printability.

We hold extensive stocks of the materials most commonly specified for CNC machining, namely aluminium alloy grade 6082, stainless steel grade 304 (A2), stainless steel grade 316 (A4), acetal (POM, Delrin) and acrylic (PMMA). Other metals we often CNC machine include copper, brass, phosphor bronze, mild steel, tool steel. We also machine a wide variety of engineering plastics, ranging from ABS, HDPE and polypropylene, through to PEEK and PTFE.

Furthermore, the versatility of CNC machining enables us to procure and machine almost any solid material, such as modelling foams, MDF and tooling boards.

For 3D printing, there are hundreds of different materials on the market, though each 3D printing technology is only compatible with only a subset of these. Furthermore, there will always be optimum operating parameters for each combination of machine and material. In order that we can maintain high quality and fast turnarounds, we have selected a portfolio of materials that, in our experience, meet the vast majority of our customers’ requirements. Having produced thousands of parts with these materials, we know how to get the best out of them.

We advise customers to decide what properties are required of the part, then look at which 3D printing technology builds parts from suitable materials, while bearing in mind the pros and cons of the different 3D printing technologies.

With five technologies in-house, and a choice of materials for all but one (we only use PA2200 Nylon in our SLS machines), we offer a very broad range of material properties for 3D printed parts. At one end of the spectrum are strong, rigid materials while, at the other end, parts can have soft, rubber-like properties.

It is worth noting that almost any rigid material can be CNC machined but not soft elastomeric materials. This is one area where 3D printing has an advantage over CNC machining. But remember there is another option for elastomeric parts: either CNC machine or 3D print a master pattern, then use this for vacuum casting one or more parts in a soft formulation of polyurethane resin.

A final point to note about materials is whether isotropy is important. If material properties need to be uniform or very similar in all three axes, then CNC machining from solid will be better than 3D printing technologies such as SLS or FDM. The other 3D printing technologies we use, namely SLA, DLP, PµSL and PolyJet, have reasonably good isotropy because the liquid resin forms stronger interlayer bonds (in the Z axis) than powder achieves when fused by the laser in SLS.

Part geometry

One of the major benefits of 3D printing is that it can manufacture parts that simply cannot be machined from solid. For example, 3D printing can build three-dimensional lattice structures, hollow features, and parts such as manifolds with complex internal passages.

Designers often assume that prototype parts with smooth, curved surfaces have to be 3D printed but this is not so. Thanks to CAD, CAM and CNC machining technologies, complex surfaces can be machined from solid. However, if both internal and external surfaces possess three-dimensional curvature, then 3D printing might be the better option. This is because machining both surfaces might require a fixture to be made in order that the part can be positioned and held securely for the second surface to be machined. Producing the fixture adds time and cost to the project.

Another point to bear in mind is that a single part can sometimes be CNC machined as two or more elements that are then joined by adhesive bonding or mechanical fixings. This approach can be useful if certain tolerances need to be tighter than could be held with 3D printing.

Similarly, if particular features require tight tolerances, they can be CNC machined as a small element that is then fixed into the main body of the part that has been 3D printed or vacuum cast. Alternatively, small features can be produced using the high-accuracy PµSL 3D printing technology, then set in a larger part that has been 3D printed using a different technology.

If customers are uncertain whether a part’s geometry lends itself to CNC machining or 3D printing, we can provide unbiased advice because we have both types of manufacturing technology in-house. Furthermore, our experience of both means we can discuss the customer’s part design and suggest ways in which small modifications to the geometry could make it more suitable (and cheaper/quicker) for either CNC machining or 3D printing. These concessions can often be made without changing the part’s function or external appearance.

Part accuracy

CNC machining is usually more accurate than 3D printing. We quote a general tolerance of ±0.1 mm on CNC machined parts whereas we quote ±0.5 mm for 3D printed parts. However, the CNC machines normally hold much tighter tolerances than ±0.1 mm and customers are welcome to talk to us if they need particular tolerances on critical features.

As well as CNC machining being more accurate than 3D printing, the part-to-part consistency is also much better, which can be important when small batches are required.

With both CNC machining and 3D printing, accuracy depends to a considerable extent on the part geometry and material.

While we quote a general tolerance of ±0.5 mm for 3D printed parts, the significant exception to this is parts created using PµSL technology. Thanks to the resolution (down to 10 µm) and small layer thickness (5-40 µm), we quote a general tolerance on parts of ±25 µm. PµSL therefore builds parts with very fine details, thin walls, sharp edges and exceptionally smooth surfaces.

A final point to note about accuracy is that, depending on the geometry, we can 3D print a part and then CNC machine specific details on the 3D printed part. This means customers benefit from the advantages of 3D printing while, at the same time, enjoying tight tolerances on critical features.

Which is quicker?

We offer an Express Delivery Service for both CNC machining and 3D printing. With our Express services, 3D printed parts are shipped the next working day whereas CNC machined parts are shipped in three working days. This suggests that 3D printing is quicker but that is not always the case. Turnaround time depends on part geometry, the quantity required and finishing options.

Surface finish and secondary finishing

CNC machined parts have smooth surfaces with distinctive visible machining marks – though applying the ‘fingernail’ test reveals the surfaces to be very smooth. Three-dimensional curves or slopes can have more pronounced machining marks, depending on the toolpath that was programmed. If need be, the appearance can be improved by light bead blasting or hand-finishing.

Parts 3D printed using PµSL technology have exceptionally smooth surfaces thanks to the high resolution and small layer thickness. However, SLS, SLA, DLP and PolyJet parts can exhibit the ‘staircase’ effect on sloping surfaces due to being built in layers. If necessary, parts can be lightly bead blasted or hand finished to provide a smoother surface.

Sometimes a part needs little more than cleaning, particularly if it is for a functional prototype. Broadly speaking, the availability of finishing options relates more to the material than whether the part has been produced by CNC machining or 3D printing. Some finishes can be applied to parts produced using both types of technology (e.g. wet painting) but others are more restricted. For instance, SLS dyeing is only available on PA2200 Nylon parts produced using SLS, while colour anodising is only available on aluminium alloy parts, which have to be CNC machined.

Applications

CNC machining and 3D printing are both versatile technologies. As such, they can be used for a variety of applications including concept models, visual models and functional prototypes, as well as end-use parts. Every project has to be considered in terms of material properties, finish, accuracy, speed and cost. In some cases, the best approach is to marry CNC machining and 3D printing to create a part that meets all of the functional and aesthetic requirements.

Talk to us

Whether you need CNC machining or 3D printing, or if you want to discuss which would be best for your parts, talk to our experts by calling 01763 249760.