Strength

If you were to make two identical parts, one by 3D printing and the other by CNC milling from solid, the machined part will be stronger. A solid, homogenous and isotropic material will always be stronger and tougher than one made by additive manufacturing. This is because of the microstructure of the solid material and its lack of porosity and internal bonds, particularly in the Z axis. When parts are 3D printed from liquid resins, the resultant material’s properties are more homogeneous than for parts produced by SLS or FDM, but the choice of materials is restricted – which, in turn, limits the material properties.

Choice of materials

Almost any solid material can be CNC machined, including metals, engineering plastics, composites (eg Tufnol), tooling board and wood. In contrast, the choice of materials for 3D printing is far more limited, depending on the technology (eg SLA, DLP, PµSL, SLS and PolyJet). 3D printing in metals, which is a very specialist area, is possible in only a relatively small range of materials.

Sometimes with prototyping you can compromise with materials, making the prototype from a slightly different grade of plastic or alloy than that planned for production, but at other times it is critical to use the exact same material. In these cases, the only feasible option might be to CNC mill the part, rather than 3D print it.

Accuracy

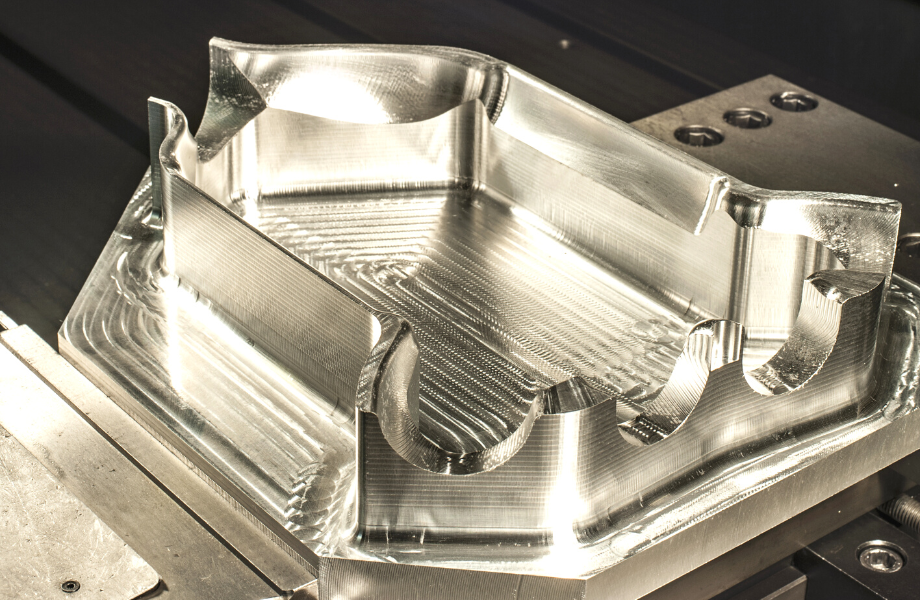

If your prototype parts need high accuracy, perhaps for functional testing, then CNC milling will be better than 3D printing. Typically, a 3D printed part will have a tolerance of ±0.5mm, whereas our quoted tolerance on CNC milled parts is ±0.1mm. However, because of the inherent accuracy of the CNC machining process, the part dimensions are usually held to tighter tolerances than this. If your part has critical dimensions, we can (more than likely) work to the tolerances specified on the drawing.

Cost

The question of cost is a difficult one because the devil is always in the detail. If the part geometry is such that all machining can be completed with a single setup, then CNC milling will probably cost less than 3D printing. But, if fixtures need to be made or specialist tooling procured, then the cost might exceed that for 3D printing. Remember, though, that the wider choice of materials and the higher accuracy might still make CNC milling the better option overall, despite it being more costly.

Multiple parts

Prototyping often calls for one-off parts to be made but what if you need more than one? Some of the time and cost associated with CNC milling relates to the preparatory work, such as checking part files, generating toolpaths and populating the machine’s automatic tool changer with the correct tooling. If multiple parts are required, this time and cost can be amortised over the production run, which reduces the cost per part.

Another advantage when CNC milling multiple parts is that the manufacturing process is extremely repeatable, so part-to-part consistency is excellent – far better than 3D printing. This can be crucial if parts are being used for functional testing in order to collect performance data.

Finishes

CNC milled prototype parts are usually left with the as-machined surface finish if they are required for functional testing. However, if a part’s appearance is important, a light bead blast can be applied or secondary finishes applied. For example, plastic parts might be primed and painted, while aluminium alloy parts could be clear or colour anodised, for greater protection.

For either aesthetic or functional reasons, steel parts can be electroplated, primed and painted, chemically blackened or, depending on the grade of steel, treated to improve the surface hardness.

Stainless steel parts can be left as-machined, electropolished or hand-polished.

Best of both worlds

CNC milling is accurate, versatile and cost-effective, yet it cannot meet every need. Nevertheless, the technology’s capabilities can be expanded when used in conjunction with vacuum casting. Polyurethane resin can mimic a wide range of plastics, from rigid glass-filled nylon through to soft elastomers. CNC milled parts can be readily overmoulded with polyurethane by using vacuum casting, for which we can 3D print the necessary master patterns.

Alternatively, CNC milled inserts can be used within vacuum castings to endow the prototype part with localised strength or accuracy where it is needed.

CNC milling and vacuum casting can be combined for prototyping, and also for low-volume production parts destined for a variety of industries.

Conclusion

As a rule of thumb, if a part looks as if it can be readily CNC milled, then it should be. On the other hand, parts with complex geometries are often better produced by 3D printing. Fortunately, we have CNC milling and multiple 3D printing technologies in-house, so we can always provide an honest, unbiased, opinion as to which would be best for your part. If need be, we can even quote for more than one option. We also have facilities for CNC turning, vacuum casting, laser cutting and traditional model making. This can be a great help for those projects when CNC milling is not the right answer, or it needs to be combined with other prototyping technologies.

Talk to us

If you need CNC milled prototype parts, or would like to discuss what the optimum manufacturing technology might be for your project, contact Prototype Projects on 01763 249760.